Printing-Neural Network Co-modelling for Personalized Biomechanical Design in Total Hip Arthroplasty

DOI:

https://doi.org/10.64504/big.d.v2i3.236Keywords:

Total Hip Arthroplasty; 3D Printing; Machine Learning; Personalized Medicine; Biomechanics; Digital Twin; Design InnovationAbstract

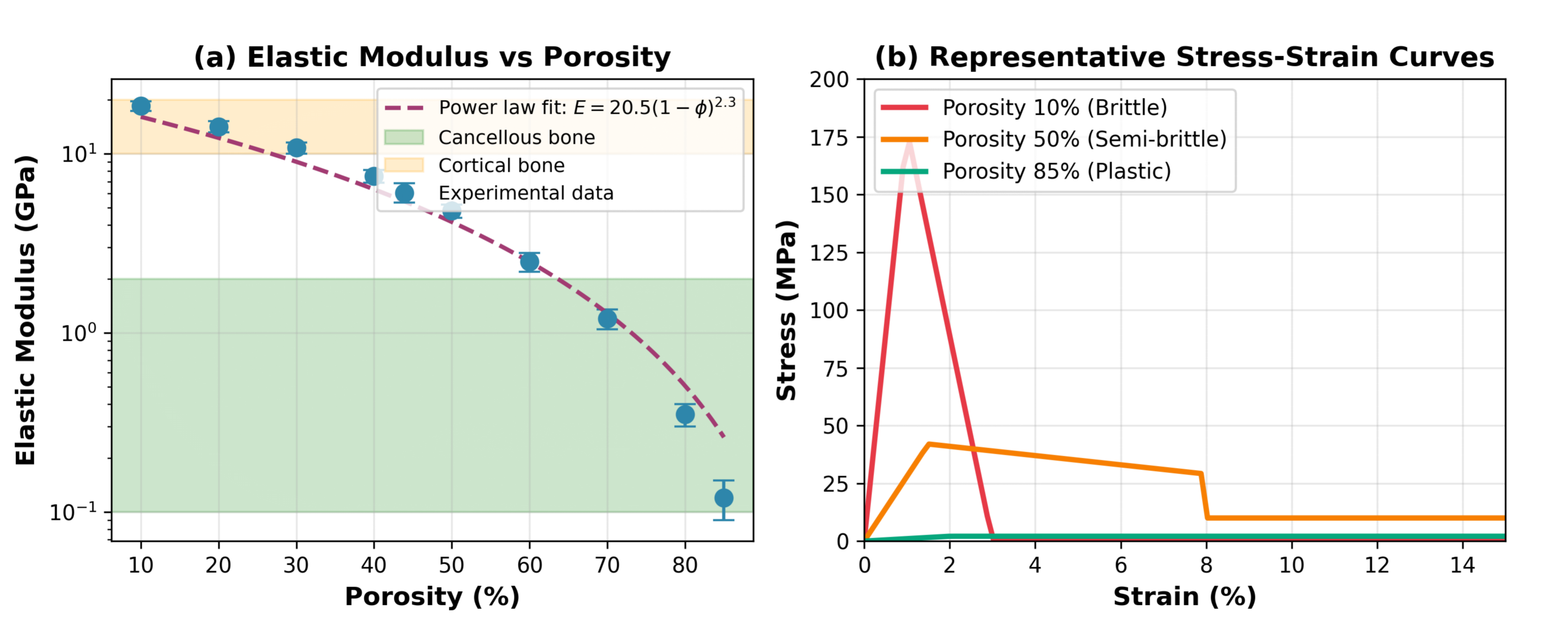

Total hip arthroplasty (THA) is the most effective surgical intervention for end-stage hip diseases, yet approximately 10-15% of patients require revision surgery due to biomechanical complications such as stress shielding and aseptic loosening. These complications stem from mechanical environment mismatch between implants and host bone, while patients exhibit substantial inter-individual variations in skeletal geometry and bone quality that standard implants cannot accommodate. This study proposes an innovative "3D Printing-Neural Network Co-modelling" (3PNN) framework to enable patient-specific preoperative biomechanical prediction and implant design optimization. First, we developed a biomimetic bone matrix material with tunable mechanical properties, achieving elastic modulus spanning the complete range from cancellous to cortical bone (0.1-20 GPa). Second, based on five key geometric descriptors (neck-shaft angle, acetabular inclination, femoral anteversion, canal flare index, and cortical thickness index), we established a parametric pelvis-femur model and generated 95 models covering patient diversity through Latin hypercube sampling. Subsequently, we fabricated this biomimetic bone model library using multi-material 3D printing and measured stress distributions after standard prosthesis implantation via digital image correlation (DIC), acquiring 120 high-quality experimental datasets. Based on these data, we trained a bidirectional 3PNN machine learning framework: Forward-3PNN rapidly predicts stress distribution from geometric parameters (R²=0.89, MAPE=9.2%), while Inverse-3PNN inversely infers bone quality from mechanical response (r=0.87 vs DXA). Parametric sensitivity analysis revealed that neck-shaft angle and canal flare index are the most critical factors influencing stress distribution. In validation with 42 retrospective clinical cases, this framework successfully guided personalized implant selection and identified high-risk patients. By integrating the fidelity of physical models with the efficiency of machine learning, this study provides a novel paradigm for personalized medical device design and digital twin healthcare systems, demonstrating significant clinical translational value and design innovation insights.

Downloads

Downloads

Published

Versions

- 2026-01-23 (2)

- 2025-07-01 (1)

How to Cite

Issue

Section

Categories

License

Copyright (c) 2025 BIG.D

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.